Mechanical Engineering Co-op at Fyto

I completed my second 6-month co-op at a Series A robotics and agriculture startup (link) as a mechanical engineer. I wore many hats and worked on:

-

Hands-on design, prototyping, & testing

-

Manual stress & bending calculations

-

Industrial circuits & electronics

-

System design and scale up for production

-

miscellaneous projects

My Projects at Fyto

Agricultural Reactor & Brewing System (A to Z)

Solids Filtration & Mechanical Separation

Industrial Circuits & Electronics

Designing, building, and commissioning a production-scale brewing system

Hands-on testing & rapid prototyping using sheet metal, shop tools, & more

Wiring & troubleshooting circuits for robots

Gantry Cart Structural Re-Design & Sheet Metal Parts

Applying Design for Assembly (DFA) Principles & Creating GD&T Drawings

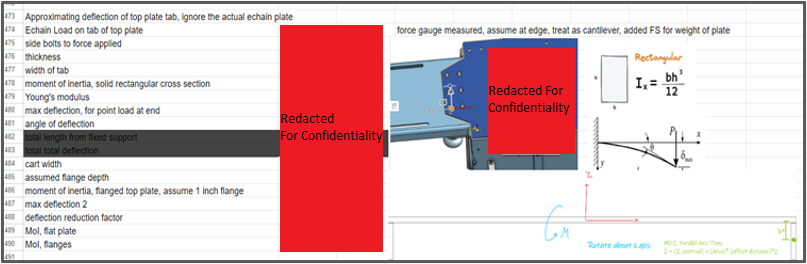

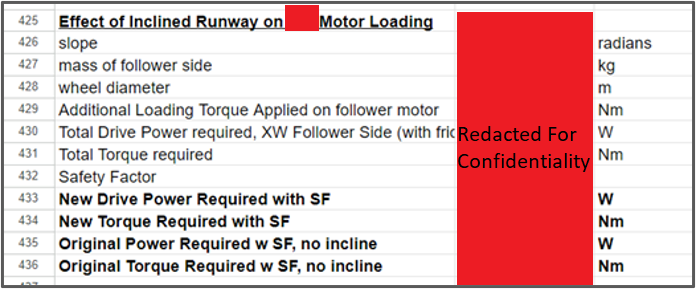

Manual Stress Analysis & Power Calculations

Structural analysis & quantitative design for parts, motor loading, and more

Miscellaneous Hands-on Projects

Bandwidth testing, hose connections, metal part assembly, & more

Agricultural Reactor & Brewing System

Design, Scale Up, & A-Z Ownership

Led the 100x scale-up of an experimental setup into a standardized agricultural brewing process, tackling motor automation & selection, plumbing, and energy cost predictions, serving as the foundation for production facilities covering 25+ acres

Skills Developed:

-

Motor Automation & Electrical Troubleshooting (motor starters, AC power, etc.)

-

Power & Hand Tools (saws, drills, etc.)

-

Design of Experiments

-

Plumbing, Piping, & Liquid Distribution Systems

-

Procurement

-

Spectrophotometry

-

Energy Cost Analysis

-

Wet Lab Experimentation

-

SOPs & Technical Engineering Reports

Purpose:

-

Design & implement a production-scale liquor extraction & brewing system

-

Scale up current process from: 1 bucket --> 1000+ gallons

-

Brewing process includes: mixing, heating, & aeration

-

-

Design a delivery system to serve 1+ acre of farmland

-

Outline the foundation to serve 25+ acres in the near future

Challenges:

-

Scaling up as is would require:

-

90kW of power (too much), 5000+ gallons of solution, tanks, etc., 8+ submersible pumps

-

--> Inefficient; Must rethink brewing process

-

How do you cost-effectively mix and aerate 1000+ gallons of liquids?

-

How do you automate mixing, aeration, and delivery on a multi-acre production facility?

-

No in-house experts on brewing barley straw extract

-

7 weeks hand-off deadline (from start to finish)

Results:

-

Designed, implemented, and standardized a production-scale liquor extraction & brewing system

-

Eliminated the need to use 90kW of power & cut material cost by 9x through re-designing the brewing process (after conducting wet lab experiments, reading literature, & challenging assumptions)

-

Wrote an SOP and trained the production and operations team on the new system

-

Shared technical reports & guides with the Plant Science team and how to scale moving forward

Solids Filtration & Mechanical Separation

Rapid Prototyping & Hands-on Testing

I redesigned the plant-water separation mechanism, tackling fluid dynamics & solids filtration, rapidly iterating through 6 prototypes using machine shop tools, sheet metal parts, and CAD, resulting in complete integration into future production bots

Skills Developed:

-

Sheet Metal Design

-

Hardware (rivets, ratchets, bolts, nuts, etc.)

-

Power & Hand Tools (saws, drills, etc.)

-

Rapid Prototyping

-

Hands-on Design & Testing

-

CAD

Industrial Circuits & Electronics

Wiring & Troubleshooting Circuits for Robots

I wired and troubleshot the safety circuit of an industrial robot, becoming familiar with complex wiring schematics, panels, and components

Skills Developed:

-

Troubleshooting 24 & 48VDC Power Systems

-

Wiring (ethernet, relays, transducers, crimping, etc.)

-

Waterproofing Cables

-

Familiarity with Industrial Safety Circuits

-

Familiarity with OSHA Safety Standards

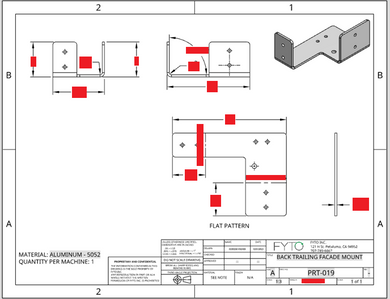

Gantry Cart Re-Design & Sheet Metal Parts

Applying Design for Assembly (DFA) Principles & Creating GD&T Drawings

I redesigned a sheet metal gantry cart, applying DFA principles, & created 20+ GD&T part & assembly drawings

Skills Developed:

-

Sheet Metal Design

-

Manual Stress & Bending Calculations

-

Master Modelling

-

CAD